Business and Technology for a better world

Sustainable biobased solutions

“We are excited to be part of the pioneer community and to help test and develop this innovation during its continued development. It fits both our sustainability strategy and our on-going exploratory work with future packaging technologies which may complement other, existing types of packaging in our packaging mix.”

Daphné Ronat, Packaging Engineer at Coca-Cola EMEA R&D Center Read more about our co-operation.

Collaboration across the value chain

Backed by industry leaders, Blue Ocean Closures is exploring new packaging solutions and enabling brands to decrease their carbon footprint. With part ownership from ALPLA Group, Magnera, Nissha, Rottneros and Elopak, we have a strong foundation for development of technology, production and markets.

Excellence in material technology

Materials from Nature

Blue Ocean Closures materials are based on cellulose fibers from sustainably managed forests, in short the same kind of fibers that you find in paper. We use the same type of food safe strength and hydrophobicity additives that are found in other paper packaging and hygiene products. In fact, the fiber content is higher than in most types of carton packaging since we do not use fillers. Cellulose fibers are strong, biobased and biodegradable and do not cause any microplastics when breaking down in nature. With our technology we can shape, integrate and exact rigid structures such as closures and other High Density Fiber™ products.

For packaging structures interacting with water, we have several ways to protect the materials and the filled goods. These range from direct contact, dispersion coating, deposition and film lamination. We are constantly developing these fields together with our suppliers and partners.

Proprietary press forming

The cellulose fibers are sintered together in a dry format using proprietary vacuum press forming technology breaking up wet and/or dry formed starting materials and relocating the fibers into the new geometry. This allows for using sturdy rigid tools, still achieving advanced shapes such as strait walls and undercuts. The high pressure promotes excellent surface quality and allows for detailed decorations and surface structures.

The Blue Ocean Closures vacuum forming technology is unique. Simple and robust, at the same time advanced and integrated. The material is stamped, draped, formed, pressed and released using multi-step tools in a fast and energy efficient process.

The roll to press delivery model gives a simple to run and high uptime concept. Since it is just high pressure and heating involved and no separation, melting, cooling or drying the technology is very energy efficient.

Efficient process

Our vacuum press forming technology is a dry, highly energy efficient way of achieving advanced shapes made from cellulose fibers. It has some very clear advantages. The process is easy to operate and fast, today down to 1,8s cycle time. It is scalable through dedicated Blue Ocean Closures presses, building on a proven machine platform from Quality Tools. Short lead times, small footprint and simple installation make it even more attractive. To improve runability, quality and energy consumption, we are not feeding back clippings into the process. To reduce pre-consumer recycling in closed or open loops, we offer a proprietary BOC RESHAPE technology that optimizes cutting geometry.

Sustainable impact

The exact effects of transferring from fossil plastics to our fiber-based materials depends on the application, but typically the carbon footprint can be reduced up to 9 times. As transports turn into electrified or biobased solutions, a growing part of the fossil carbon footprint comes from plastics. Creating biobased and recyclable solutions that can slow down this growth trend and with time turn it around is essential to reach the global sustainability goals.

Our contribution is direct with development and offers of products and materials and indirect we hope to make our contribution even bigger trough inspiring others and increasing knowledge.

There are more benefits as we, together with others, turn to forming cellulose fibers with dry processes. The technology significantly lowers the energy and water consumption and we have still only scratched the surface of what this technology can do. Important steps going forward are to reduce the pre-treatment and use even more of the fibers. In the future we can include other fiber sources than wood and use recycled fibers for non-food applications. This will help balance the available forest raw material with the growth and advantages of the technology.

Find out more about the benefits of fiber-based closures:

-

Overcap for aseptic cartons

Designed and adapted specifically for aseptically packaged products, BOC Overcap is a sustainable and cost effective solution.

PDFLink

Download

-

Design for Recycling

Recyclable as paper, our fiber-based closures are developed to support real recycling performance.

PDFLink

Download

-

Shelf visibility

Fiber-based closures capture the attention of consumers, looking to make eco-conscious choices.

PDFLink

Download

-

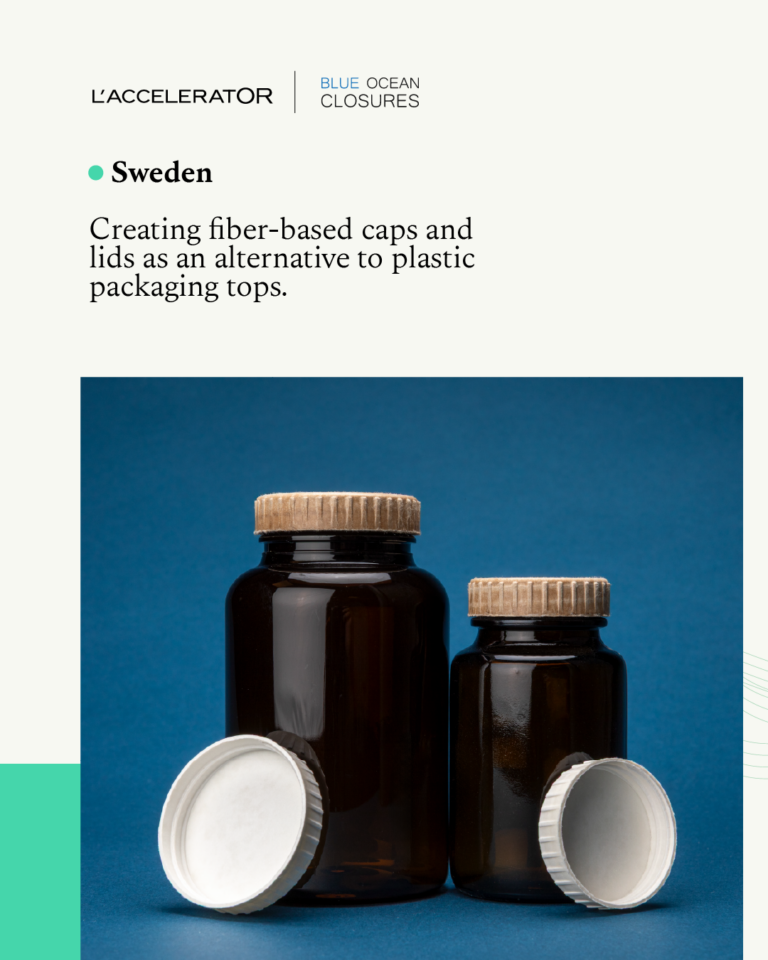

NutraCap Product Sheet

NutraCap is the world’s first and only fiber-based screw cap designed for the supplement and nutraceutical sector.

PDFLink

Download

-

Consumer appeal

Consumers make more sustainable choices and prefer fiber packaging for many good reasons.

PDFLink

Download

-

FSC®-certified Fiber

All our press formed fiber closures are produced using pulp sourced from FSC-certified forests.

PDFLink

Download

-

Brand identity

A material choice that shapes the perception of brands.

PDFLink

Download

-

Storage stability

Storage stability trials of fiber-based closures confirm exceptional resilience over time.

PDFLink

Download

-

Biodegradability

Fiber-based closures degrade in soil and seawater much faster than other caps.

PDFLink

Download

-

CO2 Reduction

Proven by Life Cycle Assessment, our fiber-based closures deliver the lowest climate impact compared to existing caps.

PDFLink

Download

-

Water Resistance by Design

We design fiber-based closures that not only lead in sustainability but also meet the real-world demands of handling and humidity.

PDFLink

Download

-

Verified Moisture Protection

Thanks to our unique manufacturing process, we can deliver the moisture protection today’s products demand.

PDFLink

Download

-

Engineered for Strength

Applying advanced press forming technology, the closures are created to perform in real-world use.

PDFLink

Download

-

Natural materials

Using forest fibers for packaging closures enables the transition away from fossil plastics

PDFLink

Download

Certificates & Documents

-

FSC®

Blue Ocean Closures AB is certified via membership in PanCert AB group for traceability CoC PanCert AB PanCert – Certifiering i hela landet. The certificate can be found here, with certification code Gruppcertifikat FSC CoC FSC Certifikat. Information about the company can be found in the certification database FSC database FSC Public Certificate Search | FSC Connect. If criticising our traceability please contact the company Query regarding traceability fulfilment Klagomål – PanCert.

Blue Ocean Closures Sustainability Policy

-

Kiwa

Blue Ocean Closures AB is certified according to ISO22000:2018 by the certifying organisation Kiwa Inspecta Sertifiointi Oy. ISO 22000:2018 is an international standard that specifies requirements for a food safety management system, ensuring that companies producing food and food packaging materials can effectively control food safety hazards to ensure the safety of the packaged food.

-

GTS – General Terms of Sale

General terms and conditions of sale “General Terms of Sale” that exclusively governs the sales of agreed products from Blue Ocean Closures to the buyer as defined on the purchase order or framework agreement.

Eco-friendly appeal

More than 90% of consumers who have tested NutraCap confirm that it has an eco-friendly appeal!